ABOUT

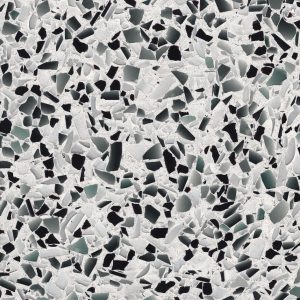

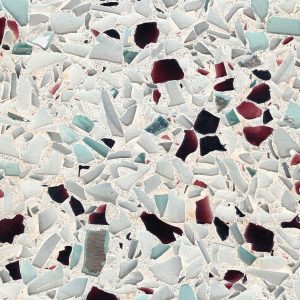

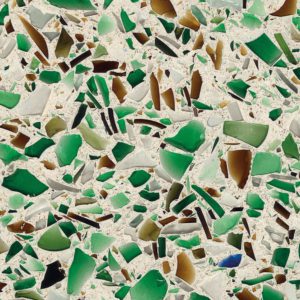

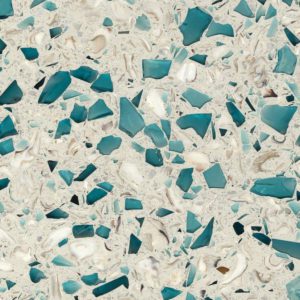

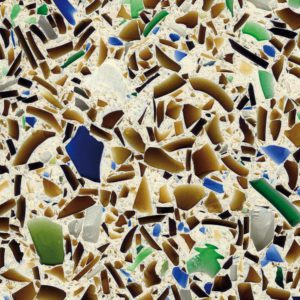

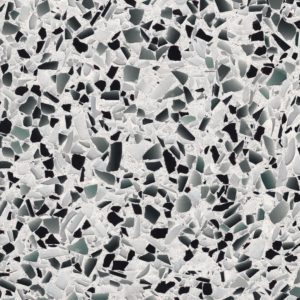

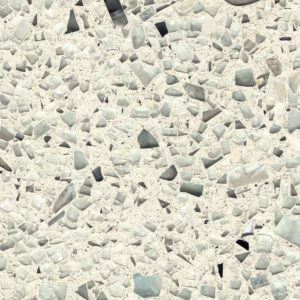

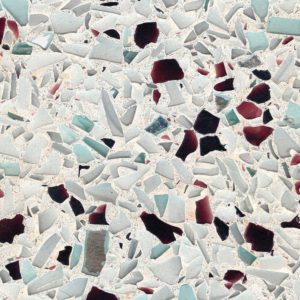

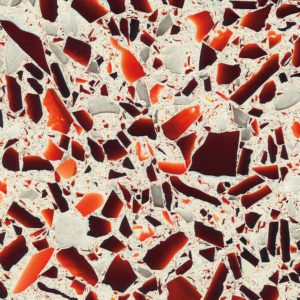

The Vetrazzo story began in 1996, when a brilliant scientist from Berkeley, California, who was fascinated by the properties of glass, invented an entirely new product. He developed an innovative mix of recycled glass that could be used to create highly durable, Beautifully coloured slabs.

HANDCRAFTED WITH CARE

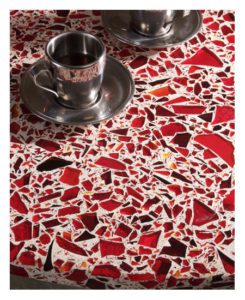

Each Vetrazzo slab is proudly produced by hand in Tate, Georgia, USA, and each is a masterpiece of engineering, design and sustainable development.

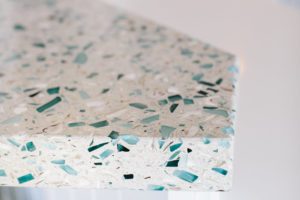

The sources of glass are carefully chosen in a process that calls for painstaking research and meticulous quality control. Then pieces of glass are introduced into the composite and placed by hand to ensure the smooth, uniform surface that enhances the beauty of the finished product.

Each Vetrazzo slab is a unique, artisan-made product that has been handled with care and expert attention to detail.

SUSTAINABLE DEVELOPMENT

Back when “green” was just a color and not a sustainable development term, Vetrazzo was already using glass refuse to create stunning surfaces.

Vetrazzo is the logical choice for consumers and professionals who care about the ecological impact of their projects, especially for LEED buildings. A slab can be made of 100% recycled glass.

Vetrazzo is committed to highest sustainability standards, using pre- and post-consumer recycled glass from local curbside recycling programs to reduce their carbon footprint.

Over the years, glass from sources as surprising and varied as old traffic lights from a city in California, all kinds of jars, windshields from cars or architectural glass from skyscrapers has gone into Vetrazzo mixes.

Vetrazzo makes sure that each slab is unique, even those of the same color blend.